ProHub Extreme Performance 6000CCS Chassis Dynamometer

The ProHub Extreme 6000CCS ( CAN Control System) Chassis Dynamometer is rated at 6000Hp (4475 KW) at 2000 axle rpm, and 13280 Ft lbs (18000Nm) axle torque. The ProHub Extreme 6000 Chassis Dynamometer is speed rated up to 5000 axle rpm, or equivalent road speeds of up to 400 mph (640 kmph) subject to vehicle gearing.

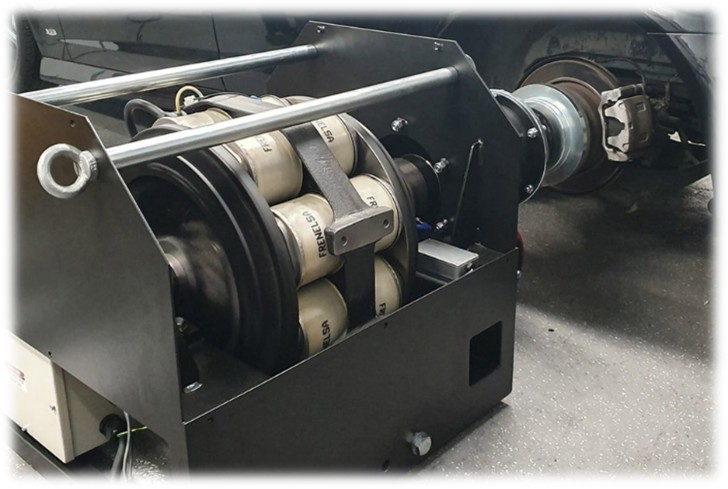

The Power Absorption Modules (PAMS) are mounted on floor plates that are attached to the workshop floor. The floor plates incorporate an enclosed track system, and anti-torque reaction and module stabilization devices.

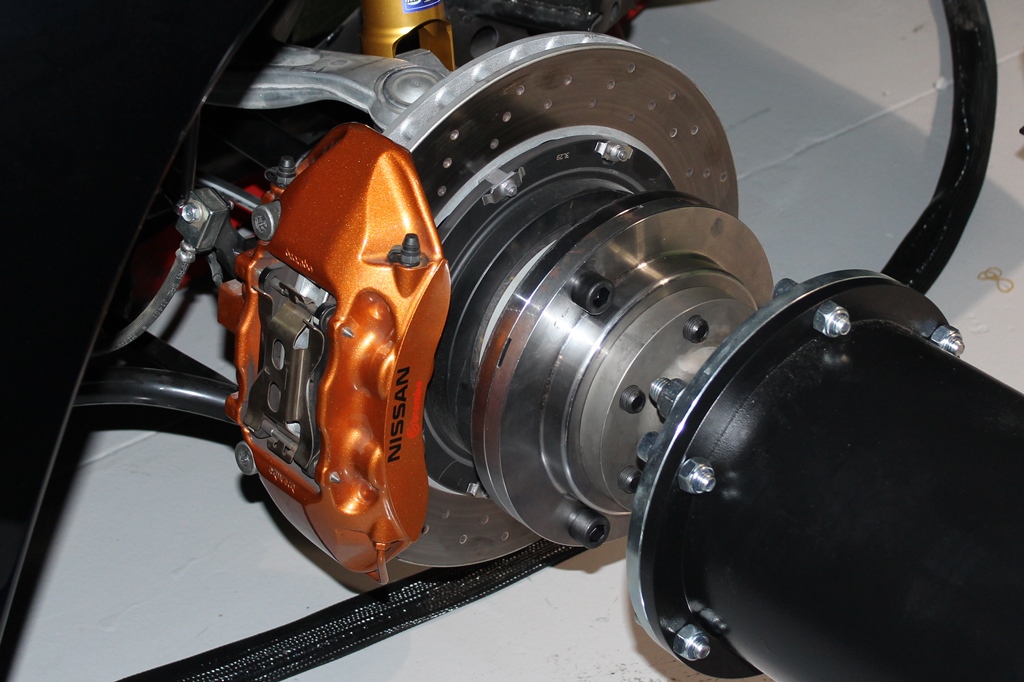

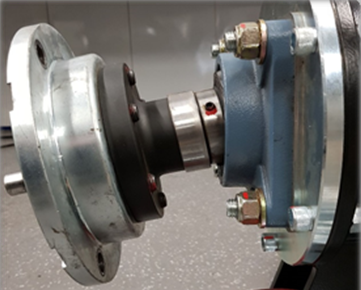

VEHICLE AXLE HUB CONNECTION

The ProHub Extreme Axle Shaft Dynamometers connect directly to the vehicle's axle hubs, via billet steel adaptors, effectively removing wheel and tyre related variables from the testing and tuning equation altogether, for absolute accuracy, and the ultimate in test data repeatability from power run to power run.

The ProHub Extreme 6000CCS Chassis Dynamometer connects to the vehicle's axle hubs, via billet steel adaptors, effectively removing wheel and tyre related variables from the testing and tuning equation, for absolute accuracy, and the ultimate in test data repeatability.

NON - COAXIAL DESIGN

All Mainline ProHub Chassis Dynamometers are a "non- coaxial" type design. This means you do not have to adjust the angle of the modules to match the camber angles of the vehicle. This allows a much quicker setup when compared to our competitors who use a coaxial type design which can also be prone to vibration due to misalignment of the modules to the vehicle.

Our non–coaxial design means it is not critical what angle the modules are attached to the car (vertically or laterally). The ProHub units incorporate a twin Constant Velocity joint arrangement contained within the extension tubes of the modules. The retarders inside the modules are off-set to ensure the connection to the vehicle can never be coaxially aligned.

This dynamometer will accommodate up to +/- 10 °camber and 10 ° toe in /out, to accommodate live axle and IRS systems.

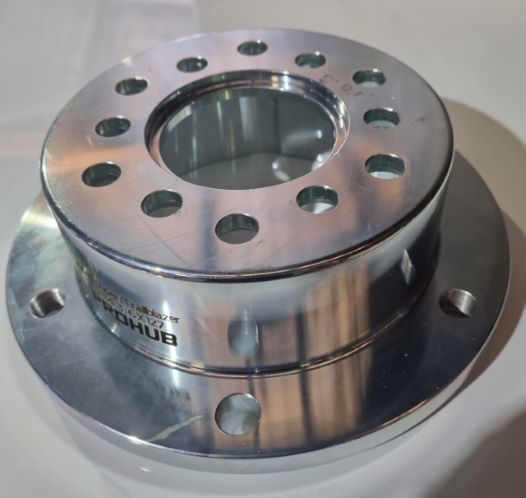

Hub Adapter Sample

CLICK HERE FOR THE LATEST LIST OF AXLE HUB ADAPTERS

HIGH-SPEED OPERATION

The ProHub Extreme Chassis Dynamometer is speed rated up to 5000 Axle Rpm or equivalent road speeds of up to 400 mph (640 kmph) subject to vehicle gearing.

EXTREME PERFORMANCE CAPABILITY

The ProHub Extreme Chassis Dynamometer is performance rated at 6000Hp (4475 KW) at 2000 axle rpm, and 13280 Ft lbs (18000Nm) of axle torque.

VEHICLE TEST APPLICATIONS

Applications for the ProHub Extreme include performance tuning, ignition timing perfection, pre-race testing, driveline torque testing, clutch evaluation, stall convertor mapping, multiple-stage nitrous injection testing, and performance product research and development. The ProHub Chassis Dynamometer can also be set-up as a very cost-effective engine testing solution, in comparison to setting up a complete engine dynamometer facility.

CAN CONTROL SYSTEM (CCS)

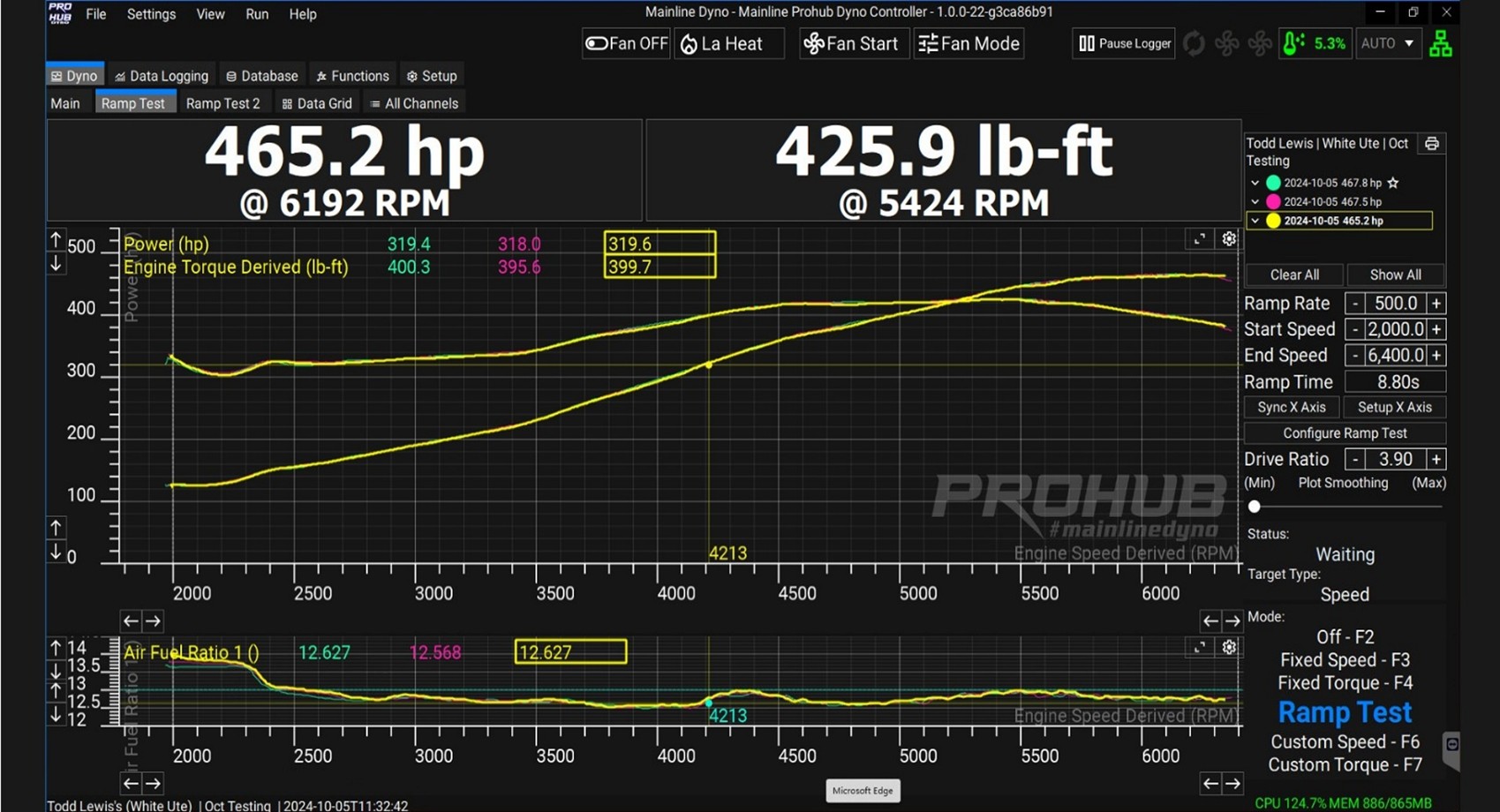

The new Mainline CCS (CAN Control System) is certainly the “next level,” in sophisticated dynamometer control and accurate data acquisition technology. The CCS features emerging and innovative hardware and software technologies that will satisfy the most fastidious operators.

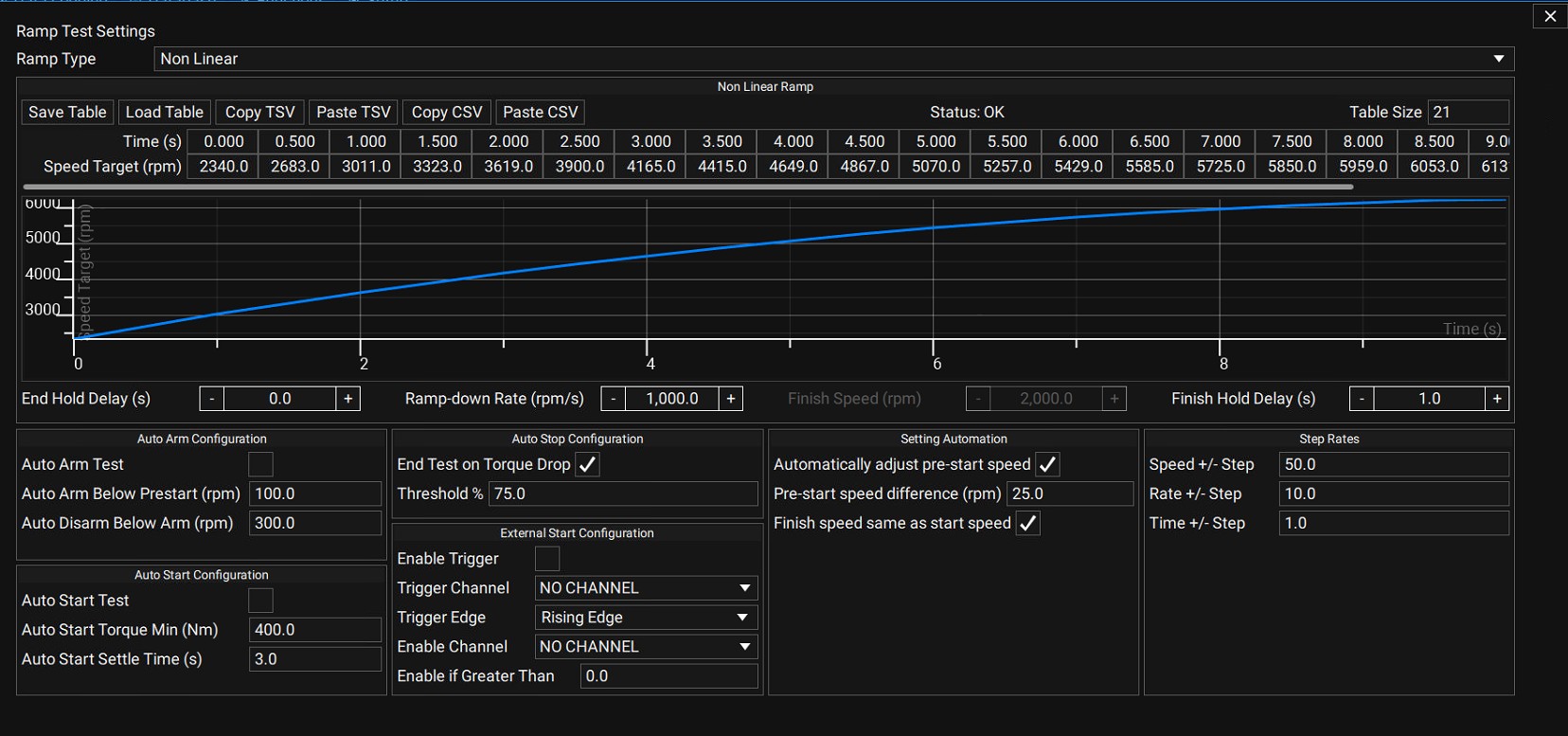

(Ramp Test Screen)

As the name suggests, this dynamometer technology is based on a robust, dependable, and efficient CAN communication network between a central head display unit and a remote CAN control unit, or multiple CAN control units, resulting in much faster data transfer speeds, faster control response and increased sensitivity for transient or intermittent data changes.

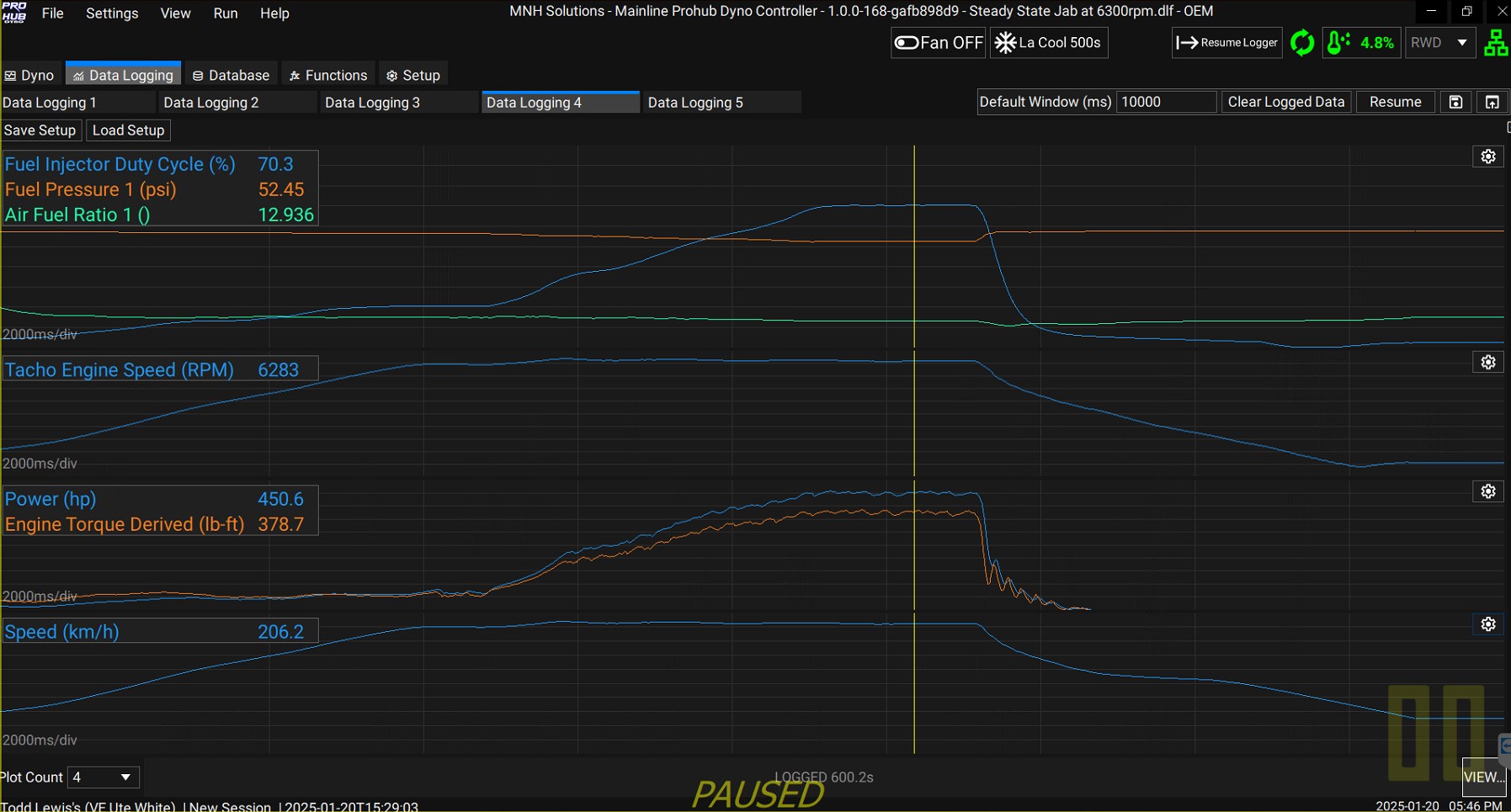

(10 Minute Continuous Data Logger)

(10 Minute Continuous Data Logger)

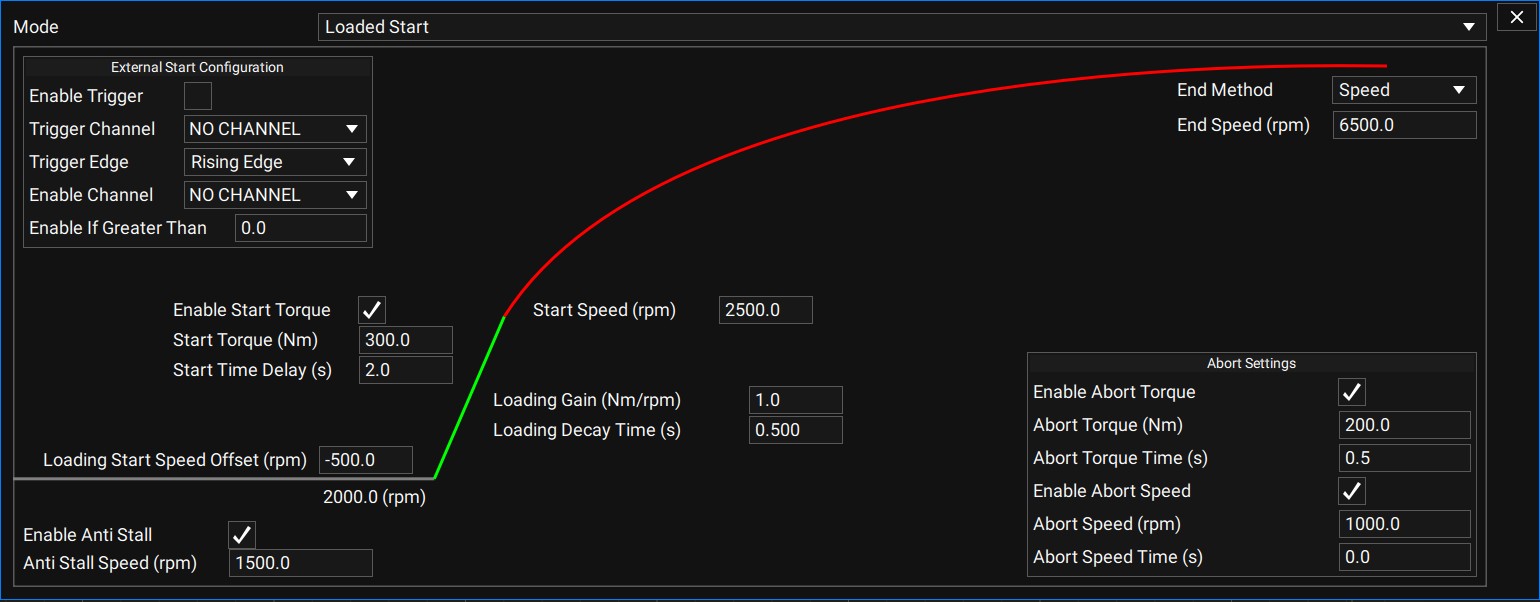

ADVANCED MODES OF OPERATION

The new ProHub Extreme Chassis Dynamometers feature very sophisticated and advanced modes of operation that include the following testing solutions:

- Fixed Speed Mode (Steady State Control)

- Fixed Torque Mode (Variable Speed Fixed Load / Torque Control)

- Linear Ramp Test (Traditional Ramp Test Mode)

- Non-Linear Ramp Test (User Definable Non-Linear Ramp Test)

- Drive Test (Road Load Ramp Test – Suited for Boosted Vehicle Applications / Acceleration Curves)

- Drive Mode (Road Load Driving Simulation - According to Vehicle Weight & Coefficient Data)

- Drag Strip Run Data Download & Run Simulations (Download Vehicle Driveshaft Curve & Simulate)

- Drag Mode (Over Distance & Time and Vehicle Weight & Coefficient Data)

- Torque Balancing / Vectoring (Torque Percentage Left to Right)

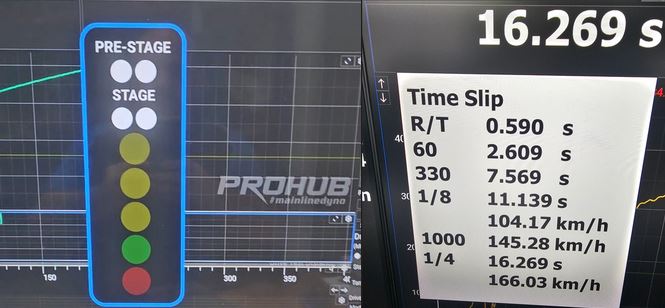

(Staged Light Start - Time Slip at Completion)

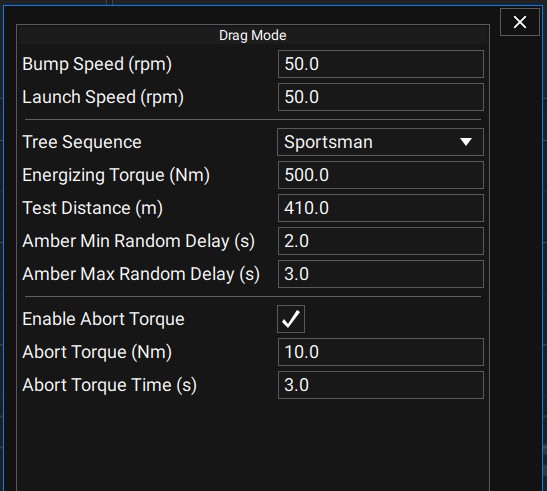

(Drag Test Setup Parameters)

(Non-Linear Ramp Test Setup)

Drive Test (Non-Linear Setup Screen

(Road Load Ramp Test – Suited for Boosted Vehicle Applications / Acceleration Curves)

ADVANCED DYNAMOMETER CONTROL STRATEGIES

The Mainline CCS (CAN Control System) employs the very latest in dynamometer control technology. The dynamometer control incorporates various strategies to ensure fast, accurate and precise control of the vehicle under test.

Eddy Current Brake Mapping: Mainlines CCS dynamometers feature fully mapped eddy current retarders. This means the performance characteristics of the eddy current retarders under all expected operating conditions are known in advance, which allows for a fully optimised and precise control strategy to be implemented across all test modes.

STANDARD INCLUSIONS

- Rolling Workstation Cabinet with Boom Arm

- Left or Right-Hand Configuration (Confirmed Upon Order)

- Twin 24” LCD Colour Monitors (Extended Desktop Modes)

- Desktop PC, Win 11 PRO OS (Solid State HDD)

- CCS Dynamometer Software Program (Mainline CAN CONTROL SYSTEM for Windows)

- Multiple User Definable Channels

- Multiple User Definable MATH Channels

- CANBUS Interface (User Configurable Inputs & Outputs)

- Wireless Trackball Remote Keyboard Controller

- Automatic Weather Station (Automatic Power Correction to Multiple International Standards)

- Vehicle Fan Control ( On / Off Switching)

- Twin Channel MAINLINE MDLC2 Wide Band Air: Fuel Ratio/ Lambda Meter (CAN Interfaced)

- 2 x 7 BAR MAP / Pressure Sensors

- Engine RPM (Derived from Axle Speed & Gear Ratio)

- Engine Tachometer Input (Inductive Clamp)

- Engine Tachometer Input (0 - 500VDC Voltage Probe)

- 2 x Sets of Axle Hub Adapters (Purchasers' Choice)

- Workshop Signage Package

- Mainline Dyno Merchandise Pack

(Optional 3 or 4 Display Monitors)

KEY FEATURES

- Up to 6000+ Horsepower & 13280 Ftlbs (18000Nm) torque capacity

- Heavy-duty floor plates incorporating an internal track system.

- Internal Anti-torque reaction and stabilisation devices. (Increased operational stability & safety)

- Mainline CAN Control System (CCS) Dynamometer & Operating Software for Windows

- Road Load, Fixed Load/ Torque, Linear and Non-Linear Ramp / Pull Tests, Drag Strip Run Time Simulations

- Drag Mode – Staged Lights Start – Time Slip at Completion

- 10 Minute Continuous Data Logger (Pause, Resume, Review Logs – Save – Recall Logs)

- User Configurable CAN inputs & outputs

- Data Grid - Multiple Digital Data Displays (Up to 54 Displays Simultaneously)

- Advanced Load Control Strategies (Precise, accurate, safe, super responsive & repeatable)

- Digital Axle Speed Sensors & Precision Load Cells (Fitted to Each Module)

- Automatic AFR / Lambda meter heater control (User-definable parameters)

- Twin Channel AFR / LAMBDA Meter (CAN Interfaced)

- AFR Fuel Types (Definable – Gasoline, Ethanol, Ethanol Gasoline, Methanol, Propane, Diesel, Hydrogen, Butane, Nitromethane)

- High-quality, heavy-duty, visually aesthetic power absorption modules (PAMS)

- Quality Frenelsa retarders (Power absorption units)

- Up to 5000 Axle Rpm / 640 kph / 400 mph test speeds (Subject to vehicle gearing)

- Fully Loaded Dyno Ramp Pulls - power calculated from measured torque (Unlike inertia-type dynos)

- Run duration (Time) can be maintained with increasing performance levels (Unlike inertia dynos)

- Maintains Engine & Driveline Thermodynamics (Unlike inertia-type dynos)

- Perfect Steady State Control – Ideal for live tuning ECU applications

- Stall Convertor Evaluation & Mapping Tests (Converter Loss / Efficiency)

- Rolling workstation control storage cabinet with boom arm

- Automatic weather station included standard (Live & continuous vehicle power correction)

- Vehicle Fan Control ( On / Off Switching)

- Wireless keyboard dyno controller (All dyno control/operation is from within the vehicle)

- Computer control system, and Windows 11 ™ Professional OS standard

- Torque & Power and other graph traces plotted live to screen / “Live as you drive” (multiple traces simultaneously)

- Graph over graph comparison tests (Power / Torque graph over engine RPM)

- Twin 7 BAR MAP/ Boost sensors (Pressure Drop Testing & Analysis)

- Multiple MATHS channels (Fully user configurable- Add your own calculation channels)

- Customer / Vehicle Performance Print Reports

SPECIFICATIONS

| FEATURE | PROHUB EXTREME 6000CCS Chassis Dynamometer |

| POWER ABSORPTION MODULES | NON-PORTABLE – FIXED TO FLOOR TRACK INSTALLATION |

| Eddy Current Retarders | 4 |

| Axle Torque Capacity Newton Metres/ Foot-Pounds | 18000Nm Nm / 13280 Ft lbs |

| Power Capacity Kilowatts / Horsepower | 4475 Kw / 6000 Hp |

| Maximum Axle Speed | 3600 rpm |

| Maximum Axle Weight Capacity Kilograms / Pounds | 2500 Kg / 5511 Lbs |

| Minimum Vehicle Wheel Track | 500mm / 19.7 Inches |

| Maximum Vehicle Wheel Track | 2900mm / 114 Inches |

| Recommended Floorspace Length | Subject to Vehicle |

| Recommended Floorspace Width (Minimum) | 7000 mm / 275.5 Inches |

| WORKSTATION / CABINET | |

| Deluxe Cabinet with Boom Arm | Standard |

| Vehicle Cooling Fan Control ( On / Off Switching) | Standard |

| Automatic AFR / Lambda Meter Heater Switch Control | Standard |

| 24" Twin Monitors (Extended Desktop Mode) | Standard |

| Triple 24" Monitors ( Extended Desktop Mode) | Option |

| Quad 24" Monitors ( Extended Desktop Mode) | Option |

| Desktop PC, Win 11 PRO OS (Solid State HDD) | Standard |

| Wireless Trackball Remote Keyboard Controller | Standard |

| COOLING FAN | |

| Vehicle Cooling Fan (Various Models) | Optional |

| Variable Speed Control (VSD) (Controls Cooling or Dyno Cell Fans) | Option |

| DYNAMOMETER CONTROLLER / DAQ SYSTEM | |

| Main Head Display Module (CAN) - Dynamometer Controller + 2 Remote CAN Modules | Standard |

| Main Head Display Module (CAN) to Computer Connection (LAN - Gigabit Ethernet) | Standard |

| Data Acquisition Module - Multiple CANBUS Interfaces | Standard |

| 2WD Vehicle Drive Applications | RWD / FWD |

| DATA ACQUISITION SENSOR INPUTS | |

| Automatic Weather Station (Automatic Power Correction to Multiple International Standards) | Standard |

| Twin Channel MAINLINE Wide Band Air: Fuel Ratio/ Lambda Meter (Can Interface) | Standard |

| Engine Tachometer Input ( Inductive Clamp) | Standard |

| Engine Tachometer Input ( 0 - 500VDC Voltage Probe) | Standard |

| VEHICLE COOLING FAN | |

| Large Rolling 3 Phase Vehicle Cooling Fan -INVERTED BLOWER (380v to 415V 50Hz– 20 AMP) | Option |

| Large Rolling 3 Phase Vehicle Cooling Fan - INVERTED BLOWER (USA 3Ph Specification – 208V, 60Hz- 40 AMP) | Option |

| Vehicle Cooling Fan Housing Assembly INVERTED BLOWER - NO MOTOR (US Single Phase Applications Only) | Option |

| Variable Frequency Drive (VFD) Control Cooling or Cell Fans | Option |

| OPTIONAL ACCESSORIES | |

| 8 Channel CAN Thermocouple Module (CAN) | Option |

| Vehicle Cooling Fan Control (Via VFD - Variable Frequency Drive- CAN OPEN Protocol) | Option |

| 24" Triple Monitors ( Extended Desktop Mode) | Option |

| 24" Quad Monitors ( Extended Desktop Mode) | Option |

| Mainline EX7 CAN Expander Module (3 Analog Inputs, 4 Digital Inputs) | Option |

| SOFTWARE PROGRAMS | |

| PC Operating System Software (Windows 11 Pro) | Standard |

| CCS Dynamometer Software Program (Mainline CAN CONTROL SYSTEM for Windows) | Standard |

| Dynamometer Software Updates | Subscription |

| Multiple Definable User Channels | Multiple User Channels |

| CANBUS Interface (User Configurable) | 1 x CANBUS (1000k Bit Rate) |

| DYNAMOMETER OPERATING MODES | |

| Fixed Speed Control ( Steady State) | Standard |

| Fixed Load Control ( Variable Speed - Fixed Torque) | Standard |

| Linear Ramp Test | Standard |

| Non-Linear Ramp Test | Standard |

| User Configurable Non Linear Ramp Test ( Download Track Drive Shaft Curve Data & Simulate Run on Dyno) | Standard |

| Drive Test - Road Load Simulation | Standard |

| Drag Racing Simulation (Over time and Distance) | Standard |

| Torque Balancing (Left to Right) | Standard |

| CAN CONTROL SYSTEM MAIN SOFTWARE FUNCTIONS | |

| Main Screen (Fixed Speed - Steady State/ Fixed Load - Fixed Torque / Road Load Simulation) | Standard |

| Ramp Test Screen (Linear, Non Linear, User Non Linear Acceleration Tests, Drag Mode Simulations) | Standard |

| Ramp Test 2 - Data Logging Screen ( Data Logging Over Engine Speed) | Standard |

| Drive Test 1 - Non PID Ramp Test ( Non Linear) | Standard |

| Drive Test 2 Data Logging Screen ( Road Load Test Over Distance) | Standard |

| Drag Test ( Drag Simulation over distance ) ( Staged Lights Start- Time Slip Issued on Test Completion) | Standard |

| Data Logging Tab Screens ( Data Logging Over Time - 4 Graphs/ Tab / 8 Data Traces/ Graph) | Standard |

| Data Grid ( Digital Data Display Screen) (10 Rows x 10 Columns Digital Data Displays) | Standard |

| Customer & Vehicle Database | Standard |

| Load / Save Test Configurations | Standard |

| Setup / Utilities | Standard |

| MISCELLANEOUS | |

| AFR Meter Extended Exhaust Probe | 1 |

| AFR Meter Exhaust Probe Restraint Strap | 2 (1 x Short, 1 x Long) |

| Vehicle Earth Strap | 1 |

| MAINLINE Internal Vinyl Workshop Banner | Standard |

| MAINLINE Internal Workshop Sign | Standard |

| MAINLINE External Workshop Sign | Standard |

| ProHub Vinyl Rope Banner | Standard |

| MAINLINE Promo Merchandise Pack | Standard |

| MAINS POWER REQUIREMENTS | |

| 3PH Voltage (Australia, Europe, Middle East, Asia) | 380 - 415V (50-63A/Phase) |

| 3PH Voltage (USA, Japan, Canada, Philippines, Others) | 208V (80A/Phase) |

| 1PH Voltage (USA, Canada, Japan) | 220V (100A) |

| Frequency | 50/60 Hz |

| PRODUCT SUPPORT & WARRANTY | |

| Tech Support - Phone, Email, Internet | *Lifetime Support(Free) |

| Manufacturer Warranty Period (Components) | 24 Months |

| Warranty Exclusions | Consumables |

| Manufacturer Warranty Period (Components) | 24 Months |

| Warranty Exclusions | Consumables (AFR Sensor) |

| PACKAGE PRICING | |

| POA | |

*Original purchaser only

CLICK HERE FOR THE LATEST LIST OF AXLE HUB ADAPTERS